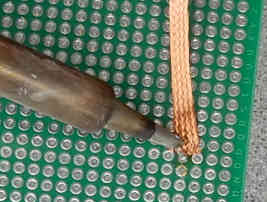

The most popular technique for removing the solder without a pump utilizes a solder wick.

Solder wick (also known as solder braid) is made of stranded thin bare copper wire saturated with flux.

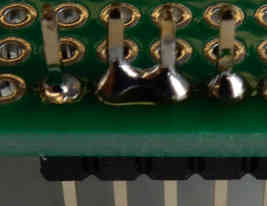

It is easy to learn how to remove solder without pump. In this technique, you need to apply heat with a soldering iron. The wick is applied in a sandwich between a solder joint and a soldering iron tip.

How to remove solder without pump depends on the circuit board and components on it.

The most popular in the USA

Weller WE1010 solder station

Hakko FX-888D soldering station

Weller WLC100 (cheap solder iron)