How to solder banana plugs depends on the type of banana plug and the thickness of the wire.

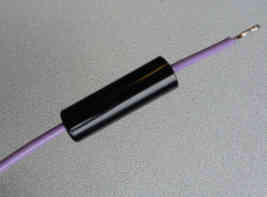

Banana plug is a cylindrical, single-wire, male connector used for joining wires to electrical equipment.

It is typically used for audio or video connection such as to connect speaker, amplifier, or other electronic devices. A banana plug has a similar shape to an RCA plug.

The most popular in the USA

Weller WE1010 solder station

Hakko FX-888D soldering station

Weller WLC100 (cheap solder iron)