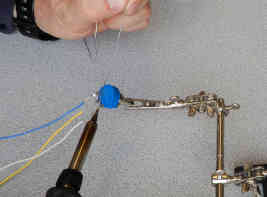

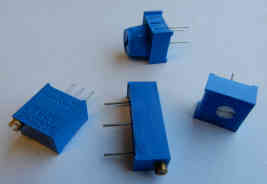

Soldering a potentiometer doesn’t require many tools. This tool is not costly. In this “How to solder a potentiometer” guide we are using the following tools:

- soldering iron

- wire strippers

- wire cutters

- heat-gun

- third-hand tools (also called helping hand tool)

- fume absorber (also known as fume extractor)

There are several different kinds of wire strippers on the market in the USA, with the cost ranging from five dollars to over a hundred dollars.

The most popular in the USA

Weller WE1010 solder station

Hakko FX-888D soldering station

Weller WLC100 (cheap solder iron)