Learning how to solder alligator clips takes just a few minutes, especially when you have the right tools.

Soldering is the best solution for connecting a wire and to an alligator clip. There are a few different ways how to solder alligator clips.

An alligator clip (also known as a crocodile clip) is a single-wire, spring-loaded metal clip used to make a connection.

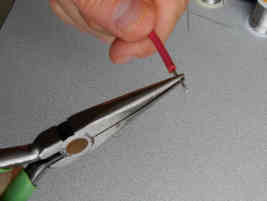

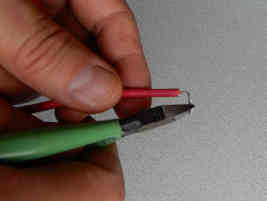

Before soldering, the wire should be prepared.

The most popular in the USA

Weller WE1010 solder station

Hakko FX-888D soldering station

Weller WLC100 (cheap solder iron)