The main function of a wire is to conduct electrical current.

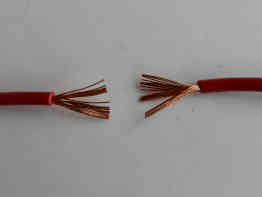

The most basic connection in electronics is wire to wire.

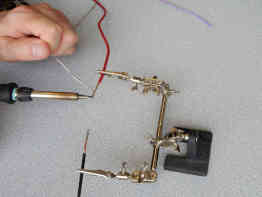

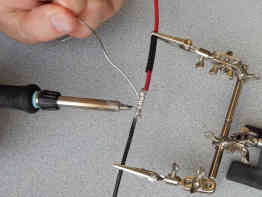

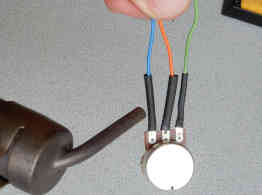

Many times you will need to solder wires to each other or directly to an electronic component.

How to solder wires depends on the size of the wire and available tools.

The wires should be soldered to assure a permanent connection. The connections should be covered to protect them against shorting and oxidation.

There are two kinds of wires:

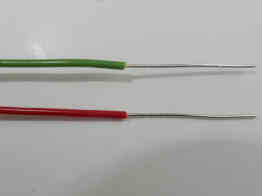

- Solid wires

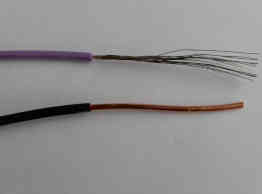

- Stranded wires

The most popular in the USA

Weller WE1010 solder station

Hakko FX-888D soldering station

Weller WLC100 (cheap solder iron)